From hospitals to detention centers, the use of nylon mattresses is everywhere. More than a choice, it’s an operational requirement for obvious reasons. High on durability, nylon is readily fluid-resistant and is easy to maintain compared to cotton or foam.

However, fire safety is always a concern. That’s why most facility managers re-check nylon mattresses for fire resistance and code compliance. While the majority of mattresses pass the established standards, one still can’t be sure.

In this article, you’ll learn :

- Why fire safety is of paramount importance with nylon mattresses

- About CPSC standards and other local codes, and

- Tips for facility managers to follow when procuring nylon mattresses.

Why Fire Safety And Code Compliance Matter for Nylon Mattresses?

Fire safety for a mattress comes from how it’s constructed. Raw nylon is prone to catching fire quickly, but a nylon mattress is pretty safe, as the manufacturers use flame retardants.

These are usually bromine-based chemicals acting as an additive to prolong ignition and slow down fire spread.

Above all, this is in line with the US Consumer Product Safety Commission (CPSC) guidelines, which mandate that mattresses meet certain standards for commercial use.

That’s why leading nylon mattresses manufacturers follow certain best practices like using internal flame barriers for high self-extinguishing capability.

It is also a fine alternative to the traditional use of flame-retardant chemicals that pose a threat to health.

Fire Safety For Nylon Mattresses: Understanding CPSC Standards And Other Local Codes

According to the CPSC guidelines, all mattress manufacturers, starting in 2007, are required to comply with pre-established standards for flammability, especially 16 CFR Part 1632 (i.e., smolder resistance) and 16 CFR Part 1633 (i.e., open flame resistance).

The 16 CFR Part 1633 is a vital standard that requires all mattresses to limit heat release during an open flame test. To comply with the standard, all nylon mattress manufacturers must:

- Add fire-barrier fabrics beneath the outer nylon cover,

- Use flame-resistant cores or flame-treated materials,

- Conduct third-party testing before releasing the stock in the market.

Such practices ensure prompt arrest of flames and maximize the time for public evacuation. Besides the federal regulations, local jurisdictions may enforce additional fire safety codes.

Take CAL TB 129 (California Technical Bulletin), for instance — a mandatory fire safety standard for the use of mattresses in all public buildings, such as nursing homes, dormitories, healthcare facilities, and correctional centers.

The standard outlines specific flammability test procedures that measure the burning behavior of a mattress under controlled conditions and measure the heat release rate.

Nylon mattress manufacturers can be subjected to hefty penalties if they fail to meet the established fire safety standards under the CPSC.

Tips For Facility Managers To Follow When Bulk Ordering Nylon Mattresses

A facility manager or a procurement officer in any organization is responsible for acquiring the necessary goods and services for day-to-day operations. When it comes to ordering mattresses, they often place a bulk order.

Here are some important tips for procurement officers and facility managers to follow when ordering nylon mattresses.

-

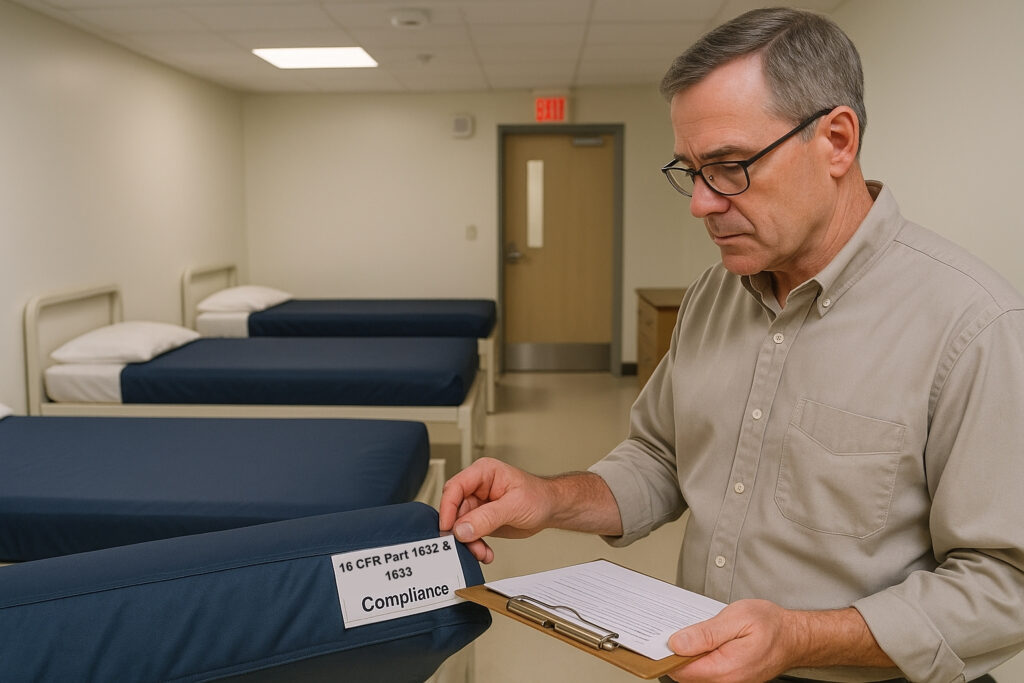

Check for the 16 CFR 1632 & 1633 compliance label:

All mattress manufacturers are expected to earn and carry the 16 CFR 1632 & 1633 compliance label for their products. Besides confirming the fire safety of the product, the labels also act as legal proof during inspections and audits.

-

Check for an integrated fire barrier or sock:

Ensure the nylon mattress uses a flame-retardant sock or internal fire barriers below the nylon cover. Nylon mattresses that rely only on surface treatments should be avoided at all costs.

-

Choose non-toxic construction options only:

Verify that a nylon mattress does not contain outdated flame retardants. Instead, choose products that use modern-day, non-toxic alternatives.

-

Check for consistent build of mattresses:

Ensure every unit matches the tested nylon mattress prototype. Any variations in density or covering material mean non-compliance.

-

Ensure easy maintenance and hygiene compatibility:

All nylon mattresses should be body-fluid resistant and compatible with hospital-grade cleaning agents, making them an ideal choice for a high-traffic environment.

-

Prioritize durability:

Ensure the bulk order for nylon mattresses comes with dedicated covers, as this adds to their durability and saves expenses over time. Additional features, such as antimicrobial coatings and tear-resistant seams, are a plus.

Frequently Asked Questions on Nylon Mattresses

-

Are nylon mattresses naturally fire-resistant?

No, raw nylon is flammable. However, nylon mattresses designed for institutional use typically include flame barriers or are treated with fire-retardant materials to meet safety standards.

-

What fire safety certifications should nylon mattresses have?

Nylon mattresses should comply with 16 CFR Part 1632 (smolder resistance) and 16 CFR Part 1633 (open flame resistance) as mandated by the CPSC. In some regions, CAL TB 129 compliance is also required.

-

How can facility managers verify fire safety compliance?

Always check for clear labeling of 16 CFR 1632/1633 compliance, request third-party testing certifications, and ensure mattresses include non-toxic internal flame barriers—not just surface treatments.

-

Are all flame retardants used in nylon mattresses safe?

Not all are safe. Avoid mattresses using older chemicals like PBDEs or boric acid. Opt for mattresses with modern, non-toxic fire barrier materials.

-

Why is fire safety crucial for nylon mattresses in institutional settings?

Shared and 24/7-use environments—such as hospitals, shelters, or correctional facilities—pose higher fire risks.

Fire-safe nylon mattresses help prevent rapid flame spread, giving more time for evacuation and ensuring code compliance.

Fire Safe and Code Compliant Nylon Mattresses Promise Best ROI

For institutional use, a nylon mattress comes highly recommended. Easy cleaning, high durability, and low sanitation costs all add to the wins.

However, fire-safe and code-compliant tags are the cherry on top, especially for facilities that use 24/7 bedding.

Here, the prime responsibility of sourcing the best-in-class, fire-safe, and code-compliant nylon mattresses lies in the hands of facility managers.

That’s why they must check if mattress manufacturers meet vital fire safety standards, such as 16 CFR 1632 and 1633, and other required certifications before placing bulk orders.

Remember, at the end of the day, it’s not just about choosing the best bedding. It’s about protecting lives, mitigating mishaps, staying on budget, and upholding institutional reputations.

Choosing a fire-safe, code-compliant nylon mattress ticks all the right boxes and promises ultimate peace of mind.